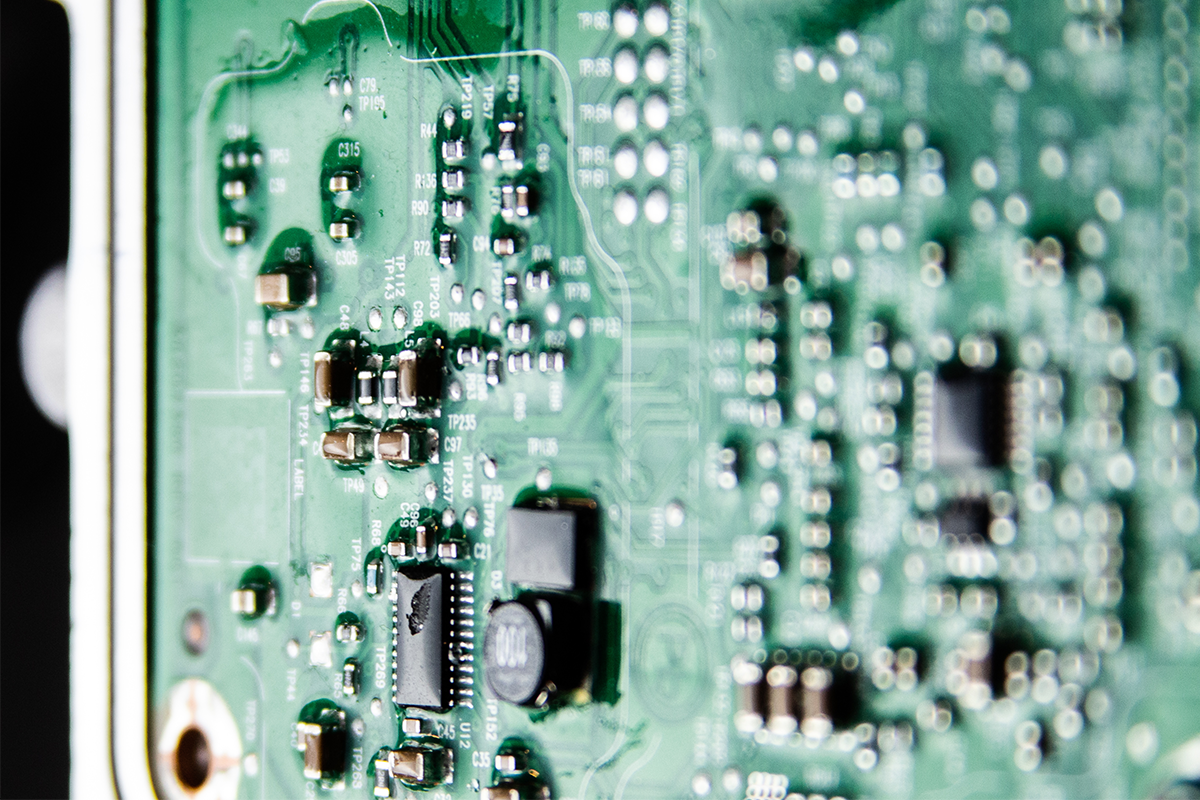

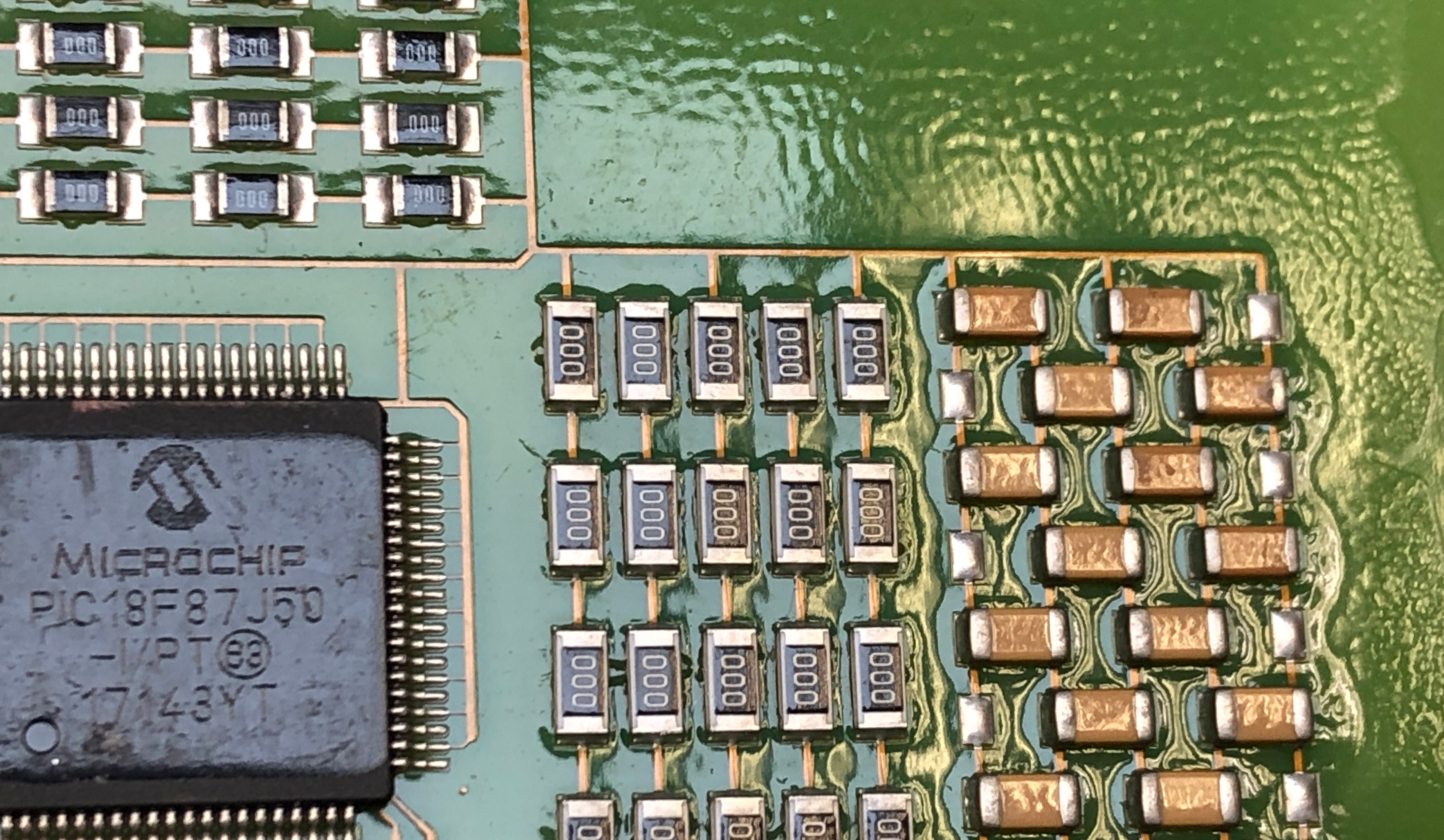

It can cover the entire board if desired and protects both the board and its parts including the component leads solder joints exposed traces and other areas of exposed metal.

Circuit board protective coating.

422c silicone conformal coating pen protects circuit board traces 5ml pen.

This makes a lot of sense because well soldermask has been used from the beginning of pcb manufacturing to protect the copper.

4 since the protective coating increases the insulation strength between the conductors it enhances the.

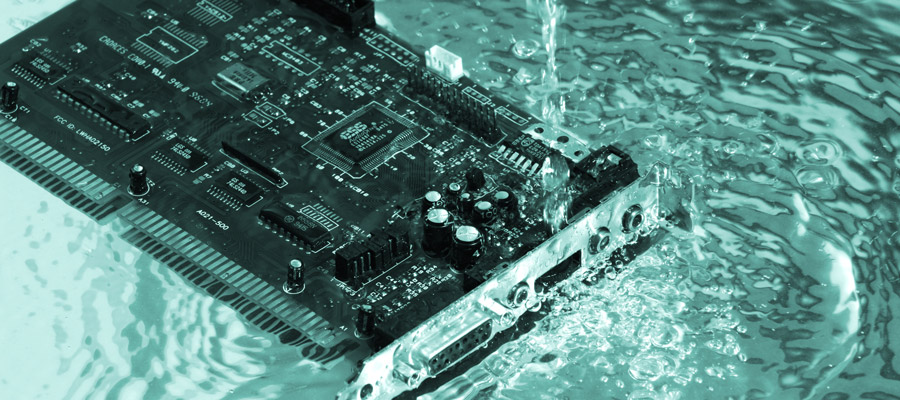

Conformal coating of printed circuit board assembly conformal coating is a protective non conductive dielectric layer that is applied onto the printed circuit board assembly to protect the electronic assembly from damage due to contamination salt spray moisture fungus dust and corrosion caused by harsh or extreme environments.

Furthermore a number of materials can be used as a conformal coating such as acrylics silicones.

Get it as soon as wed jan 6.

There are a variety of names for.

3 reduce wear during use.

Posted on 3 sep 2018.

Designed for demanding applications in electronic circuit board protection and corrosion prevention our range of fluoropolymer surface modifier coatings provide anti wetting anti stiction anti migration and anti corrosion properties.

It has great temperature stability great adhesion really ideal for protecting some exposed copper or a small modification done to a board.

Labota 3 roll high temp tape heat resistant tape polyimide masking tape kapton tape for masking soldering powder coating sublimation and insulating circuit boards 12mm x 30m.

This protective cloak for circuit boards is known as conformal coating and it can vary in its composition as well depending on the environment that the pcb will operate in.

Conformal coating is a thin film of protective material applied to a circuit board.

2 prevent the circuit board from being damaged during manufacturing assembly and use reduce the mechanical stress on the components and protect it from thermal oscillations.

Typically applied at 25 250 μm thickness it is applied to electronic circuitry to protect against moisture dust chemicals and temperature extremes.

Conformal coating material is a thin polymeric film which conforms to the contours of a printed circuit board to protect the board s components.

1 protect the circuit from extreme environments and prevent it from being affected by moisture fungi dust and rust.

The function of the shape protecting coating is as follows.

Free shipping on orders over 25 shipped by amazon.

This protects the metal from corrosion as well as shielding the entire board from spray moisture fungus dust and other contaminations from harsh environments.

Tri barrier paint is a specially formulated coating designed to protect the circuit board and its related equipment from damage thereby improving and extending their service life and ensuring safety and reliability.

Conformal coating is a protective and non conductive coating that is applied onto the printed circuit board this protects the electronic assembly from damage that may be due to contamination salt spray moisture fungus dust and corrosion caused by harsh environments.

Coatings can be applied in a number of ways including brushing spraying dispensing and dip coating.

Just as our coats protect us from unpleasant environments our circuit boards also have coats available to protect them.

We re going to take a closer look at what circuit board conformal coating is how it is applied and what that means to you as a pcb designer.

4 8 out of 5 stars 38.

Conformal coating will even help prevent damage from thermal and.